Design

Mechanical – Pneumatic – Electrical - Electronic

TVM designs and assembles its systems autonomously. It also supervises the testing, installation and after-sales assistance (including remote assistance).

During the planning phase, the creation of the software which will manage the machineis of particular importance: it must be calibrated exactly to suit the specifications of the task it will be performing.

Particular attention is paid to ensuring all the components are fully integrated (software, mechanical, electrical, electronic, pneumatic, ergonomic and safety devices). This generates and organises guidelines which create the specifications for the subsequent phase involved in building the machinery or production line itself.

By way of example, a request is handled by implementing the following planning phases:

- analysing the item to be produced or handled

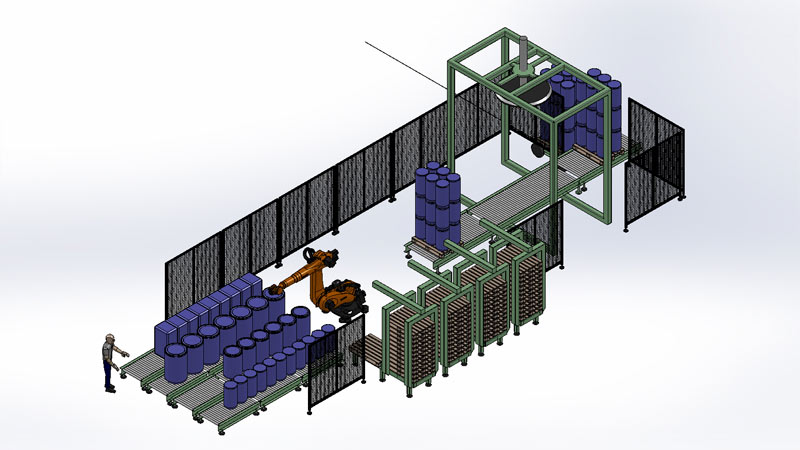

- analysing the process to be developed (palletising, machine tending, handling, assembly, pick-and-place, deburring, milling, controlling etc.)

- collecting process data (requested productivity, autonomy of the system, technical information)

- choice of robot (Cartesian/SCARA/anthropomorphic and make/model) or the use or turntables/transfer/pallet systems/belts, etc.

- designing the layout.

- presentation of the project to the customer and simulation, where needed.

These elements make it possible to define the type of system which best suits the customer’s needs.